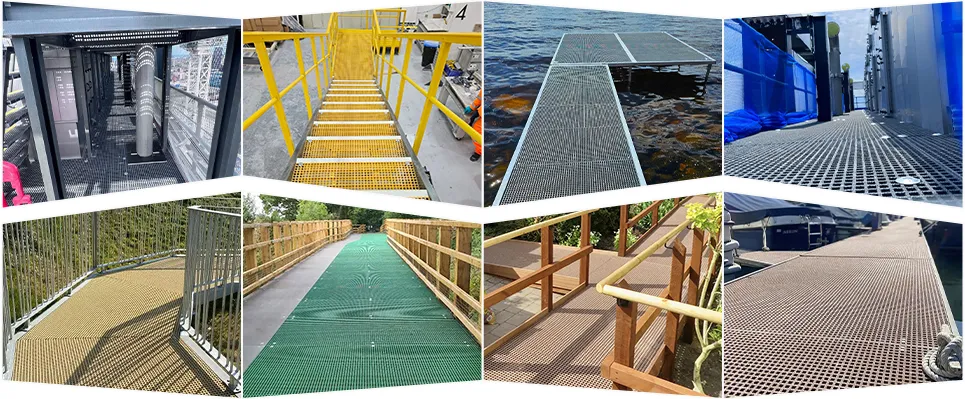

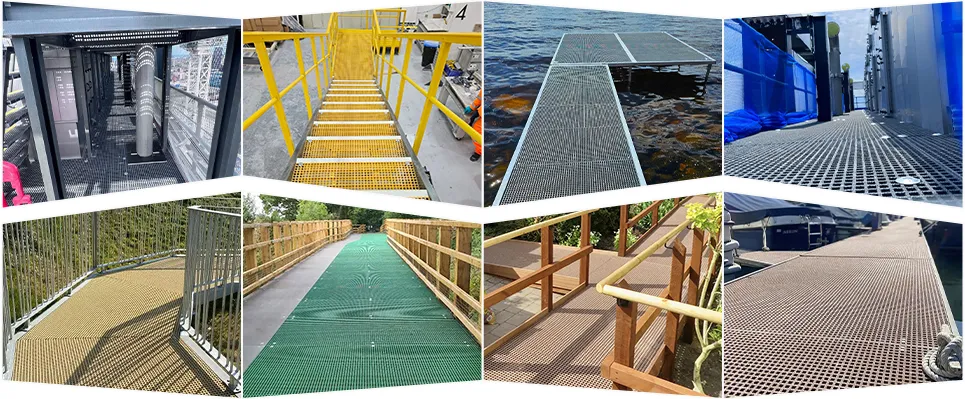

1. Corrosion Resistance One of the most significant benefits of FRP is its resistance to corrosion. Traditional concrete and steel bridge components often suffer from degradation due to environmental factors and chemical exposure. In contrast, FRP materials do not rust or deteriorate in the same way, leading to longer service lives and reduced maintenance costs.

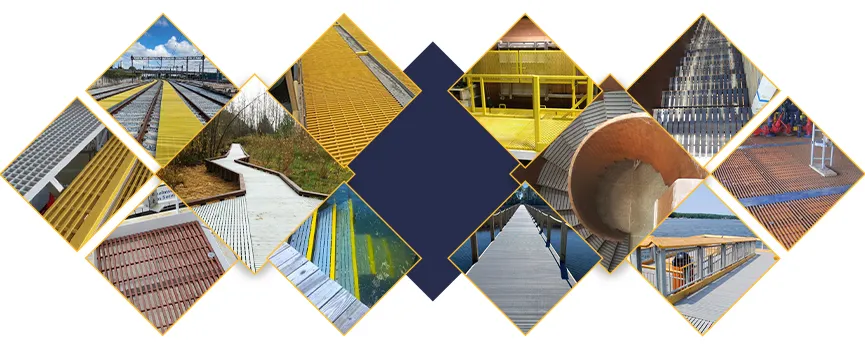

FRP is a composite material made from a polymer matrix reinforced with fibers, typically glass or carbon. This combination yields a product that is not only lightweight but also extremely strong, capable of withstanding heavy loads and harsh environmental conditions. FRP grate decking is specifically designed to provide a safe, durable walking surface while allowing for drainage, ventilation, and reduced weight compared to traditional materials like steel or concrete.

Another important classification is reverse osmosis (RO) filters. RO systems use a semipermeable membrane to separate contaminants from water. This method is particularly effective at removing dissolved solids, heavy metals, and bacteria, making it suitable for areas with significantly polluted water sources. Although RO systems tend to be more expensive and require professional installation, they offer comprehensive purification, making them popular in settings where water quality is a major concern.

water vessel filter

FRP is composed of two primary materials a polymer matrix and fiberglass fibers. The polymer provides the basic structural framework, while the fiberglass reinforcements enhance mechanical strength and resistance to environmental stresses. This synergy results in a material that is not only lightweight but also incredibly durable, resistant to corrosion, and capable of withstanding chemical attacks. These properties are particularly beneficial in industries where traditional materials like steel or concrete may fail due to rust, deterioration, or chemical exposure.

The versatility of FRP filter vessels extends to numerous applications. In municipal water treatment facilities, they effectively filter out sediment, chlorine, and other contaminants, ensuring safe drinking water for communities. In industrial settings, these vessels help manage wastewater and ensure compliance with environmental regulations.

2. Chemical Treatment Systems Chemical treatment involves adding specific chemicals to water to alter its properties. This can include coagulation, flocculation, and disinfection processes. Equipment for this purpose may include chemical dosing systems that accurately dispense necessary substances like chlorine or coagulants to ensure proper water quality.